Vietnam War: M-16, M-14, and Other Rifles – DoD Reports & Field Manuals

$19.50

Description

This extensive collection comprises 2,780 pages of official Department of Defense documents—reports, manuals, and a 1966 training film—covering the period from 1961 to 1980. The materials focus primarily on rifles employed during the Vietnam War, with a particular emphasis on the M-16 and M-14. Instead of simply focusing on these two rifles, however, the documents also discuss a range of other firearms used in the conflict.

The documentation includes information on various other rifles and weapons systems used by both American and enemy forces. This includes the Armalite AR-15 and AR-18, variations of the M14 (specifically the M14E2), several grenade launchers (the M-60, M-79, and M203), the ubiquitous Soviet AK-47, the Stoner 63 family of weapons (chambered in 5.56mm), and submachine guns (SMGs) such as the Sterling and Carl Gustav.

Initially, the M-14 served as the standard-issue rifle for U.S. Army soldiers in Vietnam. However, this situation changed following the introduction of the AR-15 by Colt in 1960. This weapon, subsequently adopted and modified by the U.S. military as the M16, was a 5.56mm caliber semi-automatic rifle. The M16 was essentially a military variant of the ArmaLite AR-15.

The transition from the M-14 to the M-16 in Vietnam stemmed from widespread dissatisfaction with the former. The M-14, while effective at a range of 500 yards using a 20-round magazine of standard NATO 7.62mm ammunition, was considered too heavy and unwieldy. Extensive research and development efforts aimed at creating a lighter, more maneuverable weapon capable of controlled bursts of smaller-caliber rounds ultimately led to the adoption of the M16 as the preferred weapon. The M14’s design, primarily focused on semi-automatic fire, contributed to this decision.

The gas-operated, magazine-fed system of the M14, while functional, was outweighed by the advantages offered by the M16 in the specific context of the Vietnam War. During the early 1960s, the U.S. Special Forces operating in Vietnam employed the AR-15 rifle, receiving overwhelmingly positive feedback on its performance. Despite resistance from the Ordnance Corps, the Armalite AR-15, a weapon initially met with some skepticism within the military establishment, was ultimately adopted by the Secretary of Defense and officially designated the 5.56mm M16 rifle. This decision marked a significant shift in small arms technology for the U.S. military.

A pivotal moment showcasing the M16’s capabilities occurred in November 1965 during a fierce engagement in the Ia Drang Valley. In this brutal battle against North Vietnamese regulars, the 1st Cavalry Division successfully repelled the enemy advance. Lieutenant Colonel Harold G. Moore, the commanding officer, attributed a significant portion of their victory to the effectiveness of the new M16 rifle utilized by his troops, emphasizing the combined impact of soldier bravery and advanced weaponry in securing the win.

The M16 rifle offered a crucial advantage with its ability to switch between fully automatic and semi-automatic firing modes, providing soldiers with tactical flexibility in different combat scenarios. While intended to match the effective range of its predecessor, the M14 rifle, the M16 demonstrated its greatest effectiveness within a shorter range, ideally under 215 yards (200 meters). The rifle utilized a smaller 5.56mm (.223 caliber) cartridge, fed from magazines holding either 20 or 30 rounds.

However, field observations revealed some limitations. Although the M16’s 55-grain, 5.56mm bullet proved highly effective at penetrating protective gear like steel helmets and flak jackets within a 300-yard range, its performance diminished considerably beyond this distance. Many soldiers reported decreased accuracy and stopping power at ranges exceeding 300 yards compared to the larger caliber .30 projectiles used in previous rifles.

Despite this range limitation, a major benefit of the M16 system was its significantly reduced weight. A soldier carrying an M14 rifle and 100 rounds of ammunition would bear a load of 16.5 pounds. Remarkably, an M16 equipped with a substantially larger supply of 250 rounds still weighed only 16.5 pounds. This considerable reduction in weight allowed soldiers and Marines to carry roughly twice the amount of ammunition for the same weight, enhancing their sustained firepower and operational endurance in the field. American soldiers in Vietnam found the M16 rifle’s cleaning requirements excessively demanding, impacting their combat readiness.

The belief was that the weapon’s burst-fire mode, while effective, suffered from accuracy issues potentially stemming from its design and stock configuration, hindering precision compared to a slower firing rate. Despite these drawbacks, the M16’s fully automatic capability was widely considered superior to the modified M14 in similar firing situations. A further shortcoming was the M16’s propensity for excessive ammunition consumption, a characteristic shared, to a lesser degree, by all burst-fire weapons.

The early deployment of the M16 was plagued by significant problems. The rifle’s unreliability was a major source of concern, as it frequently malfunctioned, ceasing fire unexpectedly. The weapon’s sensitivity to the harsh, wet, and dirty conditions of the Vietnamese battlefield led to frequent jams, directly contributing to soldier casualties. Maintaining the M16’s cleanliness in the challenging field environment proved exceptionally difficult. To address these issues, the M16 underwent modifications and a significant redesign in late 1966, accompanied by intensive training programs for soldiers on proper weapon care and cleaning techniques. These combined efforts led to a substantial improvement in the rifle’s reliability. The M16’s effectiveness was particularly evident in the close-quarters jungle combat typical of the Vietnam War. Ultimately, improved training, preventative maintenance, and design enhancements transformed the M16 into the standard-issue rifle of the U.S. Army.

On February 28, 1967, the U.S. Army officially adopted the XM16E1 as the standard-issue M16A1, a 5.56mm rifle. The M16A2 and M16A4 are the current iterations of this weapon. The provided training film, “Rifle 5.56mm, XM16E1, Operation and Cycle of Functioning TF9-3663 (1966),” offers further insight into the weapon’s operation. A twenty-minute training film from the Vietnam War era details the XM16E1 rifle, the initial mass-produced variant of the M16. This specific model is characterized by its chrome-plated bolt carrier, the absence of a buttstock storage compartment, a lack of a forward assist, an unchromed chamber, and a three-prong flash suppressor. Its performance in the challenging Vietnamese jungle environment was plagued by reliability problems, a significant factor in its eventual replacement by the more dependable M16A1 in 1967.

The XM16E1’s operational guidelines were meticulously documented in several Army field manuals. Field Manual 23-9, published in July 1966, served as a comprehensive instructional guide for the XM16E1. This manual offered detailed explanations of the rifle’s design, its operational mechanisms, and proper maintenance procedures. The manual covered a wide range of topics, including its physical attributes, step-by-step disassembly and reassembly instructions, functional explanations, ammunition types, maintenance protocols, troubleshooting malfunctions, ammunition specifics, procedures for rendering the weapon unusable by the enemy, marksmanship training, automatic firing techniques, sight adjustments, and battle zeroing.

In contrast, Field Manual 23-8, released in May 1965, focused on the M14 and M14E2 rifles, the XM16E1’s 7.62mm predecessors. This manual provided guidance for instructors and commanders on the mechanical aspects of these weapons. It included detailed descriptions of the rifles, comprehensive disassembly and assembly instructions, functional explanations, troubleshooting common malfunctions, ammunition specifications, and maintenance and handling instructions.

Finally, Field Manual 23-71, from July 1964, addressed the broader subject of rifle marksmanship, providing foundational knowledge applicable to various rifle systems, including the XM16E1, though not specifically focused on that model. These manuals collectively demonstrate the Army’s commitment to providing thorough training materials for its soldiers, reflecting the importance of proper weapon handling and maintenance, especially in a combat environment. This comprehensive guide offers a structured approach to training soldiers in rifle marksmanship, aiming to improve and sustain their individual shooting skills. It delves into the specifics of training methodologies, covering foundational rifle techniques, sighting-in procedures (battlesight zero), live-fire exercises in the field, target acquisition, formal range shooting (record firing), night shooting, and specialized sniper training.

The provided reports detail concerns raised by the Commandant of the United States Army Infantry School (USAIS) regarding the impact of new weaponry on infantry unit effectiveness. These concerns centered around three key areas: First, doubts were raised about the wisdom of equipping each rifle squad with two M79 grenade launchers, given the loss of the weapon’s multi-shot capacity compared to previous models. Second, the report highlighted significant accuracy problems and a low rate of fire with the modified M14 rifle, questioning its suitability as a replacement for the Browning Automatic Rifle (BAR) in providing the squad with necessary automatic firepower.

Third, the Commandant cautioned against replacing the modified M14 rifle with the M60 machine gun in the rifle squad without a thorough assessment of the potential effects on tactics and logistical support. To address these concerns, the Commandant ordered field tests at Fort Benning to determine the optimal composition of rifle squads and platoons, balancing personnel, weapons, equipment, and tactical effectiveness for the current operational environment. The subsequent rifle evaluation studies, dated December 8th and 20th, 1962, likely represent the results or further analysis stemming from these field tests. Research conducted by the Infantry Combat Developments Agency at Fort Benning, Georgia, revealed that internal and inter-agency communications within the US government suggested the M14 rifle was inferior to both the AR-15 and the AK-47. This prompted a request for the Department of the Army to assess the comparative strengths and weaknesses of these weapons.

In response to this request, the Department of the Army initiated a comprehensive study to analyze the tactical doctrines and operational concepts surrounding small arms, aiming to define the essential characteristics and needs for future military firearms.

Simultaneously, a global field test was undertaken by the US Army to directly compare the combat effectiveness of the AR-15 and M14 rifles in real-world scenarios. This comparative evaluation provided valuable empirical data to support the doctrinal review.

The doctrinal study, focusing on the tactical use and requirements of the rifles, examined the practical advantages and disadvantages of each weapon. This involved formulating hypotheses and strategic approaches to determine which rifle was best suited for the army’s needs and what actions should be taken concerning weapon modernization. Specific considerations included: the effective range of rifles and machine guns; the role and requirements of machine guns, especially in light of the automatic firing capabilities of rifles; the need for rifle grenade launchers; the necessity of firing from armored vehicles; the continued relevance of the bayonet and its compatibility with each rifle; the impact on squad tactics (specifically 5-7 man squads); and finally, a direct comparison of the AR-15, M14, and AK-47, ultimately aiming to recommend the best rifle for any potential equipment upgrade. This analysis assesses the suitability of introducing AR-15 or AK-47 style rifles under current circumstances and outlines the best approach to rifle development and acquisition. The core of the study focuses on the needs of the fundamental US Army combat unit: the infantry squad. While individual soldiers utilize small arms, their effectiveness isn’t solely dependent on individual skill; it’s inextricably linked to their squad’s performance as a cohesive unit. Military doctrine emphasizes collaborative teamwork, making the squad the ideal unit for evaluating small arms doctrine, usage, and requirements. In essence, the squad’s needs dictate the weapon’s suitability.

A 1964 US Army Test & Evaluation Command report examined the M16 rifle’s production quality and performance. The evaluation aimed to verify that factory-produced M16 rifles met the required performance standards, identify any flaws in design, manufacturing, or quality control, and assess their accuracy and reliability during fully automatic firing and under challenging conditions. Testing, conducted between May 26th and September 14th, 1964, generally showed satisfactory performance, although one rifle exhibited an unacceptable failure rate in semi-automatic mode.

The information regarding Small Arms Weapons Systems (SAWS) is insufficient to provide a meaningful response. More context or details about the SAWS program are necessary to offer any relevant analysis concerning the advisability of adopting AR-15 or AK-47 type rifles or to suggest an appropriate procurement strategy. The provided text only offers a historical perspective on one specific rifle test and a methodological approach to evaluating small arms, but lacks the data needed to answer the core questions. Two significant Army reports from late 1965 evaluated small arms weapons systems. The first, a comprehensive 600-page document from the U.S. Army Infantry Board at Fort Benning, Georgia (dated December 1965), compared various weapons, focusing on their performance and reliability.

This extensive analysis concluded that existing standard weapons, specifically the M14, its variant the M14E2, and the M60 machine gun, outperformed their experimental counterparts in terms of dependability. The study also highlighted the considerable increase in accuracy achieved by using duplex ammunition. Ultimately, the Infantry Board recommended against adopting any new weapon systems unless they offered a substantial improvement over the already established 7.62mm weapons. In essence, they found no compelling reason to replace the current arsenal.

The second report, from the U.S. Army Armory Board at Fort Knox, Kentucky (dated December 13, 1965), had a narrower focus. It evaluated the S-C and C-SMG weapons, assessing their suitability for use as vehicle-mounted weapons by combat vehicle crews, as well as in dismounted operations. This testing revealed that both the S-C and C-SMG offered considerable advantages over the older M3A1 .45 caliber submachine gun in terms of range, versatility, safety features, and ease of handling within the specified context. The report deemed the S-C immediately ready for adoption as a vehicle-stowed individual weapon. The C-SMG, however, required the correction of a noted deficiency before approval. Crucially, the Armory Board recommended adopting the S-C, contingent on the Army’s broader adoption of 5.56mm weapons for general ground troop use. This suggests a strategic shift towards the smaller caliber weapons was already underway.

The U.S. Air Force and, to a lesser extent, the Army’s adoption of the 5.56mm MI6/MI6E1 rifle spurred significant interest within the defense industry in developing additional 5.56mm military weaponry. This led to a surge in innovation and competition to create new firearms using this increasingly popular caliber. Following this initial wave of interest, the Department of Defense’s Advanced Research Projects Agency (ARPA) oversaw comprehensive evaluations of the S-C Weapons System between 1963 and 1964. This system encompassed six different 5.56mm weapons designed with interchangeable parts for ease of maintenance and logistical support. The Army’s assessment focused primarily on determining the overall military viability of the system, while the Marine Corps conducted more extensive field tests involving actual troops under operational conditions. Army testing revealed the S-C weapons to be accurate and well-designed fundamentally, but raised concerns about the machine guns’ power and relatively short barrel lifespan.

The S-C weapon itself was a lightweight, 5.56mm firearm utilizing a magazine-fed, gas-operated design with a rotating bolt locking mechanism. Its design allowed for both semi-automatic and fully automatic firing modes, achieving a rapid cyclic rate of 660 rounds per minute. Key features included a closed-bolt system, a compact barrel assembly, and a folding stock for portability and ease of storage.

The C-SMG, another weapon within the tested family, was also a 5.56mm weapon, employing a gas-operated, air-cooled mechanism. This submachine gun, like the S-C, used magazines for ammunition and allowed for both semi-automatic and fully automatic firing at a slightly faster rate of 750 rounds per minute. It held a 30-round magazine, fired from a closed bolt, and featured a telescoping buttstock, offering adjustability for different user sizes and situations. These tests provided valuable data for future small arms development. A 1968 Naval Research Laboratory study detailed a novel protective and lubricating coating designed for small arms, specifically mentioning its application to the M16 submachine gun. This coating was intended to safeguard M16s (and other firearms) employed by Navy SEALs and Underwater Demolition Teams (UDTs) against the harsh conditions of marine, desert, and jungle environments. The key benefit was ensuring weapons remained immediately operational after exposure to seawater, sand, dust, or humidity.

The coating itself was a carefully formulated blend of arachidyl-behenyl amine and tetrapropenylsuccinic anhydride, combined with an oil and a solvent. Its convenient aerosol packaging made it ideal for field application. This aerosol spray effectively displaced water from wet weapon surfaces. Once dry, the coating formed a tough, non-sticky layer, yet it cleverly softened to a grease-like consistency within the moving parts of the firearm, facilitating smooth operation. The researchers highlighted the flexibility of the formulation, emphasizing that its consistency could be precisely tailored by adjusting the mixture’s components. Furthermore, it demonstrated compatibility with other existing lubricants.

The coating’s exceptional corrosion resistance stemmed from its unique composition. The solid phase comprised a waxy polar inhibitor, providing a robust barrier against rust and degradation. The oil component, acting as a carrier for the inhibitor, possessed the ability to migrate to and protect even minor scratches or worn areas within the coating itself. Rigorous testing, involving both metal samples and complete weapons, confirmed the coating’s effectiveness, with components remaining undamaged after three days of continuous submersion in seawater. The report concluded by suggesting the coating was a significant advance in preserving the operational readiness of small arms in challenging environments. There is no information provided on the M14 Rifle Cost Analysis Report in this context.

A 1968 Army Materiel Command report meticulously detailed the M14 rifle’s lifecycle costs. This in-depth analysis covered the weapon’s entire history, from its conception in 1945 to its final production in 1956, revealing a total development cost of $10.9 million. The report further documented the production phase, noting that between 1960 and 1965, four manufacturers delivered 1.38 million rifles at an average unit cost of $105.15. Interestingly, the report included data on production efficiency, indicating a 92 percent learning curve slope, suggesting significant cost reductions as production volume increased. Finally, the analysis estimated annual operating costs, encompassing maintenance, repair parts, facility expenses, and labor, at approximately $50.52 per rifle.

A subsequent report, issued in October 1969 by the Aberdeen Proving Ground, focused on the evaluation of a novel 20-round plastic magazine designed for the M16A1 rifle. This engineering design test rigorously examined the performance and durability of magazines constructed from a 6-10 nylon blend reinforced with 50% fiberglass. To ensure a fair comparison, an equal number of standard and experimental magazines underwent extensive testing under various conditions. These conditions included controlled temperatures (65°F, 155°F, and ambient temperatures ranging from 40°F to 100°F) and simulated harsh environments involving mud, sand, dust, and water immersion. The report also investigated the compatibility of the plastic magazine material with various solvents and lubricants. A detailed study of cartridge positioning during firing was conducted to assess the magazine’s functionality. The results indicated that the experimental plastic magazine needed further refinement to enhance its performance in adverse conditions and to improve its durability at low temperatures.

The final report, whose title is not provided, concerns testing of 5.56mm cartridges manufactured with steel cases. Further details regarding the report’s contents are not available in the provided text. In March 1970, the Army Infantry Board at Fort Benning, Georgia, conducted a comprehensive evaluation of 5.56mm steel-cased cartridges as a potential replacement for the standard brass-cased ammunition. The study aimed to thoroughly assess the steel cartridges’ suitability, encompassing their physical properties and technical performance. This involved rigorous testing across several key areas: a detailed examination of their physical characteristics, safety protocols, compatibility with existing weapons (specifically the M16A1), performance under harsh environmental conditions (simulated by a 60-day open storage test), reliability under fire, and finally, an assessment of their impact on the soldier using them (human factors).

The results revealed only one significant drawback – a predisposition to rust. While 47 instances of case splitting occurred during the firing of 21,642 rounds, this did not hinder weapon functionality. A total of 124 malfunctions were recorded; however, the vast majority (all but three) stemmed from issues with the weapon or magazine itself, not the ammunition. Subjective assessments of blast, flash, noise, and recoil indicated no significant differences between the steel and brass cartridges. Interestingly, the steel-cased rounds exhibited a greater ejection distance, traveling further to the rear and right compared to their brass counterparts.

Ultimately, the report concluded that the 5.56mm steel-cased cartridges were deemed suitable for adoption by the US Army, at least under moderate climatic conditions. The minor issues identified, primarily the rust susceptibility and the slightly altered ejection pattern, were considered acceptable trade-offs given the overall performance and compatibility demonstrated during the testing. The relatively low malfunction rate, largely attributable to weapon or magazine problems, further supported this conclusion. The study provided strong evidence for the feasibility of using steel-cased ammunition in the M16A1 rifle. The U.S. Army Material Command issued a report in January 1975 that investigated the unexpectedly rapid barrel wear observed in M16A1 rifles used in Vietnam. This accelerated deterioration wasn’t solely due to standard mechanical wear and tear; the harsh, corrosive Vietnamese climate significantly exacerbated the problem. To address this issue, the army opted for a solution involving chrome plating the interior of all replacement rifle barrels.

In order to establish reliable quality control standards, a testing process was implemented. Barrels from three different manufacturers were subjected to rigorous firing tests, continuing until the barrels reached the point of failure. After every 1,000 rounds fired, the accuracy of each barrel was meticulously assessed. The average spread of bullet impacts—a measure of accuracy—served as the key metric. This data allowed the army to define acceptable tolerances for new barrels and to determine a precise definition of when a barrel was considered worn out. This established a quantitative benchmark for barrel lifespan and quality control.

The report, therefore, details a response to a significant logistical and operational challenge encountered during the Vietnam War. The accelerated barrel wear threatened the effectiveness of the M16A1 rifle, and the report documents the investigation, the chosen solution (chrome plating), and the development of a standardized testing procedure to ensure the longevity and reliability of future barrels. The focus on the average extreme spread of bullet dispersion highlights the importance of maintaining accuracy as a primary performance indicator for the weapon. This systematic approach underscores the army’s commitment to resolving the problem and improving the weapon’s reliability for future deployments.

A 1977 study conducted at the Army Command and General Staff College in Fort Leavenworth, Kansas, examined the ideal role of individual firearms within mechanized infantry squads. The core objective was to assess the need for a lighter, more compact assault submachine gun to boost the squad’s firepower and overall effectiveness. This research drew upon both historical combat analyses and contemporary military doctrine to define the optimal function of personal weapons in relation to supporting weaponry systems.

The analysis hinged on two key factors: the kinds of effective fire needed from small arms and the typical engagement distances at which this fire would be necessary. These factors were broken down into more granular components, including the impact of fire on targets, the sustained effectiveness of that fire, the tactical deployment of rifle squads, the accuracy of small arms at various ranges, the inherent characteristics of the weapons themselves, and the officially defined roles of these weapons.

The study’s findings concluded that incorporating a smaller, lighter assault submachine gun would significantly improve the mechanized infantry squad’s mission accomplishment. This improvement would stem from increased accuracy and sustained firepower, greater tactical flexibility, enhanced mobility and maneuverability on the battlefield. Moreover, the researchers predicted a positive psychological boost to soldier morale and confidence due to the improved weaponry. In short, the report advocated for a new weapon based on its potential to improve battlefield performance in several key aspects. This document from 1980 details the Army Research Institute’s findings on rifle marksmanship research conducted primarily between March 1978 and June 1980 at Fort Benning. The report’s core focus is on identifying and addressing shortcomings in existing basic marksmanship training and its associated equipment. Specifically, it highlights issues such as inadequate teaching methods, insufficient practice opportunities, and a lack of clear feedback on shooting performance.

The research involved several experiments exploring potential solutions. These solutions encompassed streamlining fundamental shooting techniques, creating a more effective zeroing target, implementing better diagnostic tools to identify shooter errors, providing immediate feedback on shots fired, improving the transition from aiming to firing, and enhancing the quality of instruction overall.

Based on this research, a completely new basic rifle marksmanship training program was developed and rigorously tested. Remarkably, this new program resulted in a 29% improvement in final exam scores (record fire). This success led to its immediate implementation within the Infantry Training Brigade at Fort Benning, followed by Army-wide adoption.

The report doesn’t end with this success, however. It also frankly addresses persistent challenges that still needed to be overcome to achieve truly optimal basic marksmanship training. Finally, it outlines the ongoing research aimed at developing advanced marksmanship training programs for individual soldiers and entire units.

Separately, a 1980 evaluation report, also from the Army Research Institute for the Behavioral and Social Sciences, assessed two competing training programs for both M16A1 rifle and .45 caliber pistol use within field units. This FORSCOM/US Army Marksmanship Unit evaluation focused on the effectiveness of these alternative instructional methods at the operational level. The report likely detailed the comparative strengths and weaknesses of each program, potentially informing decisions about which approach to adopt more broadly. A study of soldiers from the 1/504th Infantry Battalion (Airborne) participating in rifle and pistol training programs revealed significant findings regarding training effectiveness.

The participants, all male soldiers from a combat-ready unit, were divided into groups receiving different training regimens: a full Advanced Marksmanship Unit (AMU) program, a partial AMU program, and standard annual qualification training. The results clearly demonstrated that soldiers undergoing the complete AMU program achieved superior performance and exhibited higher levels of confidence compared to those in the shortened AMU or standard training groups. Both AMU groups outperformed the standard training group. Consequently, the researchers concluded that military units could leverage the AMU program’s points of instruction (POIs) effectively, choosing between the full or partial program based on available time and resources, to enhance soldier performance beyond current standards. The full AMU program, when feasible, yielded the most substantial improvements in both the number of qualified soldiers and their overall proficiency levels.

A separate report from 1980 by Mellonics Systems Development detailed an analysis of M16A1 rifle performance to inform improvements in marksmanship training. This research involved rigorous testing of sixty randomly selected rifles, encompassing serviceability checks and accuracy evaluations under controlled conditions. Subsequently, nine rifles representing a range of performance (good, average, and poor) were chosen for further in-depth analysis. These tests covered various aspects, including zeroing procedures (with both standard and long-range sights), trajectory analysis, the use of rimfire adapters, the impact of barrel stress, shooter error assessment, and evaluation of performance by novice soldiers. The report’s primary audience was those responsible for developing marksmanship training programs and related equipment.

Finally, a list of additional reports suggests a broader body of research on weapon systems and ammunition: one on the aerodynamic properties of 7.62 mm NATO ammunition (1967), another on the sensitivity of rifle gas systems (1971), and a third correlating breech erosion with M16A1 rifle accuracy (1975). These additional studies provide further context for understanding the complexities of small arms performance and the ongoing efforts to optimize marksmanship training. This collection of documents from 1975-1977 focuses on various aspects of the M16A1 rifle’s performance and maintenance.

The research delves into the impact of microscopic imperfections in the barrel’s surface (projectile engraving mutations) on the weapon’s accuracy. Another study examines how the rifle’s barrel temperature affects its precision. A third piece of research explores the forces involved when a soldier fires the rifle, aiming to design a standardized testing fixture. Furthermore, the collection includes work on calibrating a tool to measure barrel wear (breech erosion) in chrome-plated barrels and measuring the shock generated when firing the M16A1 with the M203 grenade launcher attached. The effects of different lubricating materials on the rifle’s function are also investigated, alongside a broader analysis of the relationship between barrel wear (bore erosion) and the rifle’s accuracy. Finally, the provided text transcriptions of the documents allow for comprehensive searching across all the reports, making it easier to find specific information within this body of research on the M16A1 rifle.

M14 and M16 Rifle Development: 1961-1980

Timeline of Events (1961-1980) related to the M14 and M16 Rifles, based on the documents:

- 1945-1956: Development of the 7.62mm M14 rifle, totaling $10.9 million in development costs.

- 1960: Colt introduces the AR-15 semiautomatic rifle, which would later be developed into the M16.

- May 22 – July 31, 1961: Rifle Squad and Platoon Evaluation Program conducted at Fort Benning. Concerns are raised about the M79 grenade launcher, the M14’s accuracy and rate of fire as a substitute for the BAR, and the tactical and logistical impact of substituting the M60 machine gun for the M14.

- December 8 & 20, 1962: Infantry Combat Developments Agency at Fort Benning issues two Rifle Evaluation Study reports. These reports indicate the M14 rifle may be inferior to the Armalite AR-15 and the Soviet AK-47. The studies lead to a worldwide comparative evaluation of the AR-15 and M14. The studies consider various factors including range requirements, the role of the machine gun, rifle grenade launchers, and the impact on doctrine with smaller rifle squads, the potential advantages of the AR-15/AK-47, and the best course of action for rifle development and procurement.

- 1963-1964: The Advanced Research Projects Agency (ARPA) directs Army and Marine Corps tests of the S-C Weapons System, a family of 5.56mm weapons. Army tests are limited to military potential, while the Marine Corps conduct service tests. S-C weapons are found to be accurate, but machine guns are marginal in operating power and barrel life.

- May 1965: Department of the Army issues Field Manual FM 23-8, detailing the U.S. Rifle 7.62mm, M14 and M14E2.

- May 26 – September 14, 1964: US Army Test & Evaluation Command conducts a comparison test of production-line M16 rifles. Concludes rifles perform well except for one excessive failure-to-fire during the reliability test.

- November 1965: 1st Cavalry Division uses M16 rifles in the Ia Drang Valley battle. LTC Harold G. Moore credits the M16 with contributing to their victory.

- December 1965: United States Army Infantry Board (USAIB) publishes Small Arms Weapons Systems (SAWS) report that finds the M14, M14E2, and M60 are more reliable than their counterparts in SAWS, recommending against adopting new systems until there’s a significant improvement over the 7.62-mm systems.

- December 13, 1965: U.S. Army Armory Board report on testing the S-C and C-SMG as vehicle-stowed weapons finds the weapons to have advantages over the current M3A1 submachine gun in range, safety, handling, and general utility, with the S-C found suitable for Army use as a vehicle-stowed individual weapon.

- 1966: US Army Training Film TF9-3663 on the XM16E1 rifle is released.

- July 1966: Department of the Army issues Field Manual, FM 23-9 on the XM16E1 rifle, covering its description, operation, maintenance, and marksmanship training.

- July 1964: Department of the Army issues Field Manual, FM 23-71, on Rifle Marksmanship, providing detailed training guidance.

- Late 1966: Redesign of the M16 rifle is implemented to improve its reliability, along with efforts to train troops in its care and maintenance.

- February 28, 1967: The United States Army formally adopts the XM16E1 rifle as the standard United States M16A1 rifle, 5.56mm.

- 1967: Aerodynamic Characteristics of the 7.62 MM NATO Ammunition M-59, M-80, M-61, M-62 report.

- 1968: Naval Research Lab releases a report on a preservative-lubricant for small arms, particularly for the M16 submachine gun used by SEAL and UDT personnel to protect them during sea water and sand/jungle exposure.

- October 1968: Army Materiel Command report analyzes the costs of the M14 rifle system.

- October 1969: Aberdeen Proving Ground report details results from the engineering design test of 20-round plastic magazines for the M16A1 rifle, finding the need for improvement in performance in adverse conditions and for increased material durability.

- March 1970: Army Infantry Board report assesses the suitability of 5.56-mm steel-cased cartridges, finding them suitable for Army use in intermediate climate conditions but with a rust susceptibility, and some split casing during testing.

- 1971: Sensitivity Study of Rifle Gas Systems report.

- January 1975: Army Material Command report analyzes dispersion measurements for the M16A1 rifle with chrome-plated bore. It establishes acceptance and rejection criteria for new barrels, and the amount corresponding to a worn out barrel.

- 1975: A series of technical reports released including: Correlation of Breech Erosion Gage to Accuracy for M16A1 Rifle with Chrome Plated Barrel Bores, Projectile Engraving Mutations and Their Relationships to Accuracy of the M16A1 Rifle, External Barrel Temperature of the M16A1 Rifle, and Study of Man-Weapon Reaction Forces Applicable to the Fabrication of a Standard Rifle Firing Fixture, Calibration of Breech Erosion Gage for 5.56mm Chrome-Plated Bores.

- 1976: Reports released on Firing Shock Measurements on the M16 Rifle/M203 Grenade Launcher System and Evaluation of Lubricating Composites for the M16A1 Rifle.

- 1977: Army Command and General Staff College report analyzes the infantry’s need for an assault submachine gun, finding a compact, lightweight submachine gun would enhance the capability of the mechanized infantry squad.

- 1977: Bore Erosion and Accuracy of M16A1 Rifle report.

- 1978-1980: Army Research Institute at Fort Benning conducts a research program on M16A1 rifle marksmanship, culminating in a new basic rifle marksmanship program that improves record fire performance by 29%.

- 1980: Two reports released: The FORSCOM/US Army Marksmanship Unit M16A1 Rifle and .45 Cal Pistol Marksmanship Training Evaluation, which evaluated two programs of instruction and found that the FULL-AMU program produced better results, and Adequacy of M16A1 Rifle Performance and Its Implications for Marksmanship Training, which recorded firing test results for M16A1 rifles and produced data for simplified marksmanship training procedures.

Cast of Characters (Principle People Mentioned):

- LTC Harold G. Moore: U.S. Army Lieutenant Colonel. He is noted for lauding the M16 rifle’s contribution to the victory in the Ia Drang Valley battle in November 1965.

- Commandant, USAIS: The Commandant of the United States Army Infantry School at Fort Benning. This individual is responsible for expressing concerns and initiating evaluation programs for new weapons.

Key Weapon Systems and Ammunition Mentioned:

- M14 Rifle: Standard rifle initially used by the U.S. Army as involvement in the Vietnam War grew. 7.62mm, semi-automatic, magazine-fed, gas-operated, effective range 500 yards.

- M14E2 Rifle: A modified version of the M14.

- Armalite AR-15: Semi-automatic rifle that was the basis for the M16.

- M16 Rifle: U.S. military’s version of the Armalite AR-15. 5.56mm, selectable full or semi-automatic fire, effective range 215 yards or less (most effective) Initial version had reliability issues and evolved with redesign and training into a standard issue weapon.

- XM16E1 Rifle: The first mass-fielded version of the M16 with reliability issues.

- M16A1 Rifle: Upgraded and more reliable version of the M16, developed in 1967.

- M16A2/A4 Rifle: Current versions of the M16 rifle.

- AK-47: Soviet/satellite rifle mentioned in comparison studies with the M14 and AR-15.

- M79 Grenade Launcher: A weapon evaluated for its role in the rifle squad.

- M60 Machine Gun: A machine gun that was considered as a replacement for the M14.

- M203 Grenade Launcher: A grenade launcher system used in conjunction with the M16 Rifle.

- S-C Weapons System: A family of 5.56mm weapons.

- C-SMG: A 5.56mm submachine gun tested for vehicle stowed use.

- 5.56mm Ammunition: The cartridge used by the M16 series of rifles. Both brass-cased and steel-cased cartridges were evaluated.

- 7.62mm Ammunition: The cartridge used by the M14 rifle.

Related products

-

Tokyo Rose: Department of Justice Prosecution Files

$19.50 Add to Cart -

World War II: Adolf Hitler and Operation Foxley – British Assassination Plot

$19.50 Add to Cart -

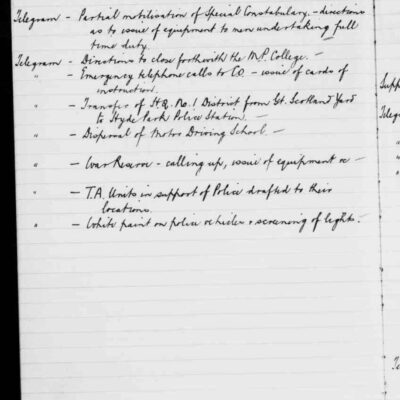

World War II: Scotland Yard War Diary from 1939 to 1945

$3.94 Add to Cart -

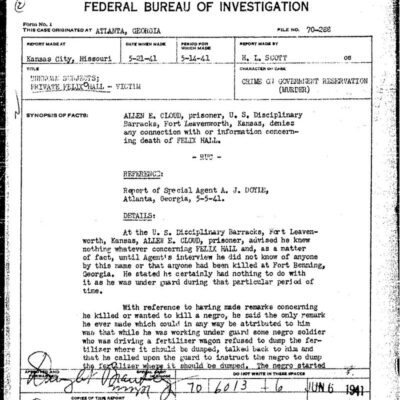

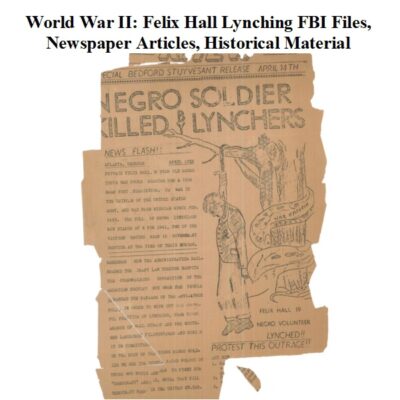

World War II: Felix Hall Lynching – FBI Files, Articles, Historical Records

$9.99 Add to Cart